Last updated on January 9th, 2023 at 04:30 pm

Packaging Specifications

1

Briquette material must be bundled together with enough banding to minimize material loss while being handled, and be stacked on a pallet without affecting the stability of the bundle.

2

Baled material must be compacted and banded or wire together to minimize material loss while being handled. It must also be stable enough for stacking purposes.

3

Bundles must be strapped to the pallet. Pallets and boxes must be of sturdy construction and maintain their integrity while handling.

Proper Banding

Bales (TALDON) and High Density Bales

- Banding – min 6, max 10

- 10-gauge aluminum

- 5/8”x.020” steel

- 5/8”x.036” plastic

- 13 gauge steel

- Bales should separate into sections when banding/wire is cut

- Bales of uniform size are preferred.

- Use of support sheets (cardboard, plastic, etc) is not acceptable.

Biscuits (TALDACK)

- Banding – banding slots in both directions (two vertical, min 4 horizontal)

- 5/8”x.020” steel

- 5/8”x.036” plastic

Gaylord Boxes

- Material in Gaylord boxes will not be accepted unless prior approval from TAA is given.

- Maximum Size - 50 in x 50 in x 48 in tall

- Minimum Size - 24 in x 24 in x 24 in tall

- Box must be on a pallet

- No cover on box preferred

- Steel band around center of box preferred

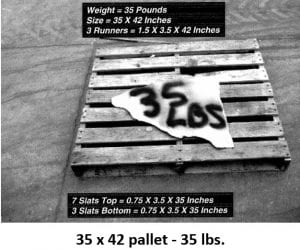

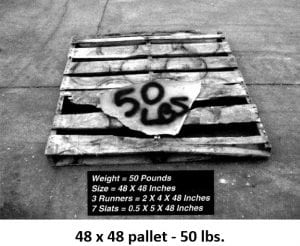

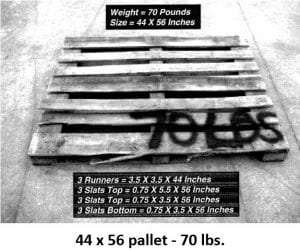

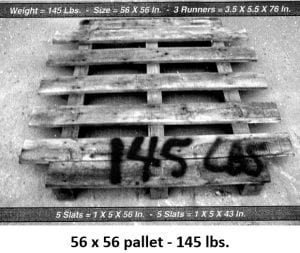

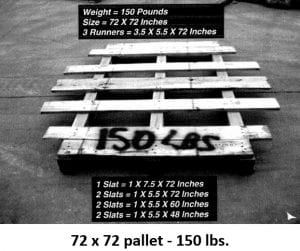

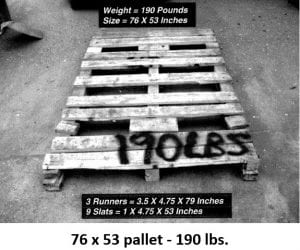

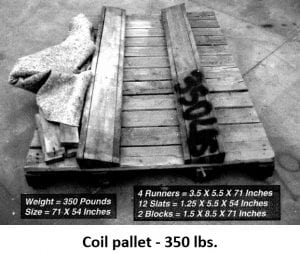

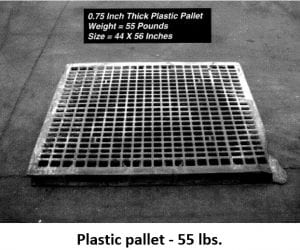

Pallet Specifications

For more information on ISRI scrap types please see: Nonferrous | ISRI