Last updated on February 15th, 2023 at 03:29 pm

Inspections & Sampling

Material Downgrade/Rejection

Material Downgrades

Material Downgrades 5% and under are automatically accepted. Supporting documentation for the downgrade will be communicated the following business day.

Material that does not meet the requirements of the specification of the purchase order may be subject to rejection. If the material can be deemed acceptable by a downgrade of the material, the vendor has options available.

- Option 1 - The vendor can accept a downgrade of the material accompanied by an adjustment to the terms of the purchase of the material.

- Option 2 - The vendor can arrange to have the material picked up and removed from Logan property if the downgrade is greater than 5%.

Rejected Loads

Due to space limitations, all rejected material must be removed as soon as possible. Material rejected at the time of delivery will automatically be reloaded on the truck it was delivered on. Material rejected and off loaded will have three working days to be removed from Logan Aluminum. If the rejected material has not been removed in the allotted time, a truck will be scheduled for pickup and the material sent collect to the vender or location of the vendor’s choice. The vendor is responsible for all costs of shipping and return for the rejected material.

Rejectable Items

These items include, but are not limited to:

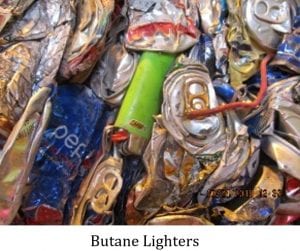

- Butane Lighters - Butane lighters can have the strength of three sticks of dynamite when

submerged into molten metal. More commonly found in UBC loads, and sometimes seen on the

floor of the truck when unloading. - Explosives Ammunition/Rocket Tubes/Detonators – Explosion potential for both shredding

and melting operations. The assumption is, if there is one in the load there may be additional

ones that are not visible and there is no guarantee that there are no live rounds ( Does not include

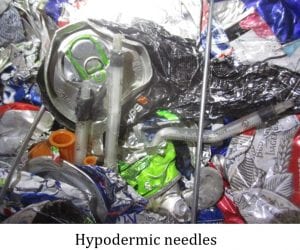

air bag inflators – see note Air Bag Inflators later in this section) - Medical Waste – Needles, surgical gloves, medical waste, etc will not be accepted. Logan Aluminum is not

set up to process/deal with this type of material. - Radioactive Materials or Materials displaying Radioactive Warning Labels – Materials that

fail to pass the gate radiation detector inspection process and any materials with a radioactive

warning label will be rejected and returned following regulatory guidelines. - Closed Containers – Closed containers can include but are not limited to oxygen tanks, fire

extinguishers, crimped closed tubing, Freon tanks, aerosol cans, beer kegs, and baseball bats.

Closed containers can develop extreme pressure when submerged in molten metal. Once the

pressure reaches the burst limit of the vessel it can spray molten metal or present additional

explosion potentials. - Liquid storage and transfer vessels that can contain residual liquids (fuel/oil/antifreeze) –.

These tanks have both a potential closed container risk as well as the risk associated with

flammable liquid/fumes. Material should be shredded and allow to be dried or verified that no

fuel is present prior to melting, or rejected. - Fertilizer/Oxidizers – Fertilizer is an oxidizer. When an oxidizer (Nitrates/Sulfates etc.) are

mixed with molten metal a violent reaction will occur. It takes very little material to create an

explosion. - Hazardous Chemicals – Hazardous chemicals such as PCB’s, pesticides, asbestos, etc. or loads

that are labeled to include these materials will not be accepted - Snow/Ice/Excessive Moisture - Excessive moisture in the form or snow/ice/liquid can result in inaccurate moisture sampling, making it difficult to determine the moisture content of the material.

- Sleeved Cans/Bales/Poly-Coated - Material that is decorated with plastic/paper sleeves in excess will not be accepted. This material can create a safety concern as it is processed in our system.

- Trailer Damage - Van trailers delivering scrap that contain damaged floors are subject to rejection if Logan personnel deem it is unsafe for lifts/operators to enter a trailer.

- Lids- Any UBC containing can lids in excess are subject to rejection.

- Beverage Product Termination- Any material found to have unopened/full beverage containers from product termination facilities will be rejected.

Material Downgrade/Rejection Examples

Any supplier whose material is found to contain a sealed tank, egregiously heavy gauge material, or radiation are subject to immediate disqualification. Any supplier whose material causes damage/downtime to a machine center caused by a contaminant is subject to disqualification by Logan/TAA as well. Material currently in inventory at Logan from said supplier would also be subject to rejection.

General Inspection

Inspection Report Documentation

Documentation of the inspection reports will be supplied in order to expedite settlement of issues such as weight discrepancies, downgrades and rejected loads.

Quality Verification

Each load will be inspected upon delivery. The material will be verified that it meets the criteria established within the purchase specification agreement. The material will be inspected for items such as excessive moisture, oil, dirt, garbage, plastic, glass, non-aluminum contaminants, aluminum fines, nitrates, sulfates, safety hazards, packaging issues, contamination of any kind. The results of the material inspection may be subject to a load rejection or if agreed upon, the material may be downgraded. Issues noted during inspection will be photographed and documented to the shipper.

During inspection, a determination will be made as to whether the material meets the purchase specification. If the load is determined to meet expectations, no deduction will be made regarding contamination.

Items that will be subject to immediate rejection of the entire load if found during the inspection are butane lighters, aerosol cans, hypodermic needles, live ammunition, explosives, gasoline, propane bottles or other gas cylinders or bottles, medical waste / infectious materials, radioactive material, PCB’s, mercury, asbestos, Freon, poisons, acids, fertilizer, rodents, excessive corrosion, oxidizers, flammable liquids, closed containers, crimped tubing, lead paint and other questionable items. The presence of these items poses a safety hazard to personnel and is not debatable.

Material Sampling

Moisture Sampling

UBC should be dry; therefore, it is suggested that material not be stored or processed outside.

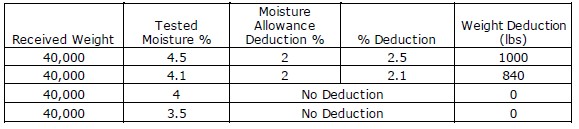

A random sample will be pulled from each load to calculate a moisture percentage. Shipmentswith moisture in excess of 4% will be subject to a weight deduction or rejection. The deduction

will equal the tested moisture percent minus 2%. See example below.

Radioactive or Hazardous Material

Material delivered to Logan Aluminum and found to be contaminated by radiation will be handled according to Logan policy. Any material triggering either of the two Logan radiation detectors will be rejected. Scrap, raw materials or packaging must not contain or be contaminated with hazardous material. TAA/Logan will have the right to revoke the acceptance of the material at any time. All costs and liability associated with radioactive material will be the responsibility of the supplier.

Any delivery which fails radiation after 3 attempts at gate 4 and gate 2 is held on plant site according to Kentucky State policy. Logan Aluminum's Environmental/Health/Safety department will take over at this point to acquire required documentation. Once state permitting has been achieved the driver will then be released to return the load back to its originating location.