Last updated on February 15th, 2023 at 03:02 pm

Meltable Specification Manual

How to find our location

Contact UsGeneral Requirements

Meltable Specification Manual

Safety Data Sheets (SDS)

Per the requirements of 29 CFR 1910.1200, the supplier, vendor, or importer must provide a Safety Data Sheet (SDS) for the metal or scrap sold to TAA or Novelis, or must verify that the material meets the posted SDS on this site.

Prime & RSI

Specification Details

- Safety will not be compromised for any reason. Personal injury, environmental destruction and equipment damage will not be tolerated.

- Each load will be inspected upon delivery.

- Each producing plant must develop best practices so that the chemistry provided to Logan accurately represents the bulk metal chemistry. Chemical samples MUST be from the heat shipped. Each plant must ensure that enough samples are taken at casting time so that a sample is available for each heat shipped. Substituting a sample from a heat with a similar chemistry is unacceptable.

- All scrap must be clean and free of dross, excessive mold release agents, pot room bath, salts, corrosion, dirt, gravel, aluminum "fines", un-melted scrap, nitrates, sulfates, oxidizers, fertilizers, unknown powders or residues, volatile substances, ammunition, non-aluminum contaminants, closed containers, crimped tubing, PCB's, radioactive materials (2 times Background radiation) and aluminum-lithium alloys.

- Lime must never be used as a mold release agent or refractory trough coating.

- Double poured Prime or RSI sow or sow with rough edges will be rejected.

- No Residual lubricant may be present on scrap, unless otherwise agreed upon. Scrap must be free and clean of oil or lube. Based on Logan's compliance to SMACT standards certain furnaces are regulated as "Clean Charge" furnaces only. "Clean Charge" is defined in SMACT regulations (40 CFR 1503).

Clean charge means furnace charge materials, including molten aluminum; T-bar; sow; ingot; billet; pig; alloying elements; aluminum scrap known by the owner or operator to be entirely free of paints, coatings, and lubricants; uncoated/unpainted aluminum chips that have been thermally dried or treated by a centrifugal cleaner; aluminum scrap dried at 343°C (650°F) or higher; aluminum scrap delacquered/decoated at 482°C (900°F) or higher, and runaround scrap.

- Painted, lacquered or coated scrap is not acceptable.

- Paper interleaved or wrapped scrap is not acceptable. This includes coils.

- Physically unloading the scrap and releasing the delivering carrier does not imply acceptance of the load or the shipped weights. Logan has the right to reject all or part of a load if the specifications described in this manual are not met.

- The mixing of alloys in a shipment is not acceptable.

- Mixing of producers or ingot shape in a shipment is not acceptable.

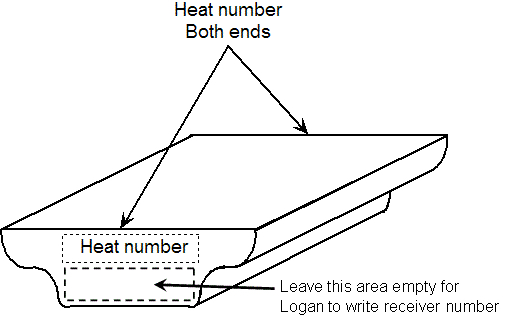

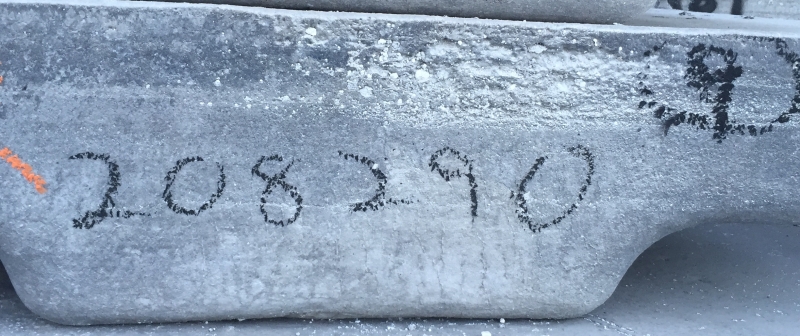

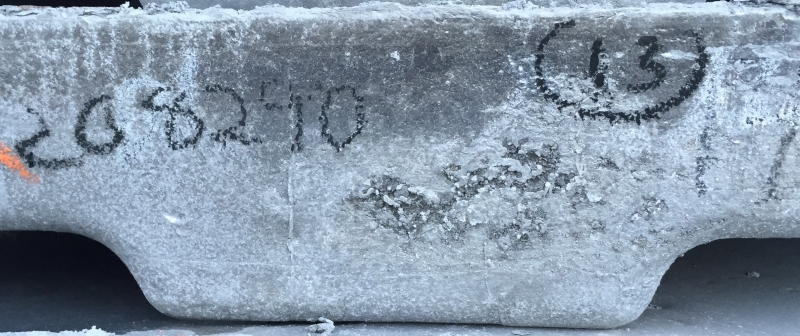

- Each RSI sow must have the heat number marked on both lifting ends. The heat number must be centered and near the top of the ingot lifting ends. Heat marking on sow must be consistent with data listed on COA sheet. Numbering must be legible. Numbering must be approximately 2-1/2 to 3 inches in height. (see example below)

- Each sheet ingot or coil must be marked legibly and permanently with manufacturers heat number and the 4 digit AA alloy code.

- Each bundle of standard ingots, pigs and slab must be marked legibly and permanently with manufacturer's heat number. (see example below)

- Any banding used to hold pieces/ingots together is preferred to be aluminum, steel, or nylon. Material with rusted or corroded banding are subject to rejection.

- Ingots more than 300" long or more then 58,000 lbs. must be cut before charging. Any ingots over 10,000 lbs must be able to be lifted by the 4-point ingot grab. The grab can grip ingots between 50 and 80 inches wide. The minimum ingot length for the grab is 90 inches.

- Unskimmed RSI or primary aluminum sows are not acceptable.

- Coils must not be more than 86" wide and must not weigh more than 58,000 lbs.

- Certificates of analysis must accompany all shipments. Representative chemical samples must accompany all RSI shipments. Material outside of chemical composition as stated on the purchase order will be rejected.

- No double or multiple pour sows or ingots are acceptable. Logan has a zero tolerance and this metal will be rejected immediately.

- High profile sows will not be accepted by Logan Aluminum and they will be rejected. See section 5.0 for how to determine if a sow is high or low profile.

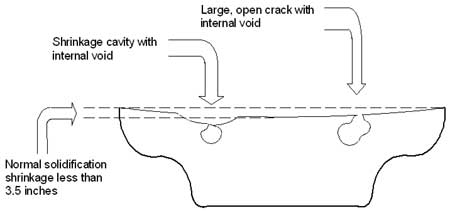

- Sows are to be free of excessive shrinkage cavities and large cracks. See the detailed specification 6.0, which follows.

- Ingots must not be wedged front to back and/or side to side because when stacked they will lean and possibly fall when moved.

- Sows must not be higher in the center (crowned) than on the sides. Crowned sows when stacked are unstable and may fall.

- Lips or edges must be less than 1" to allow for stacking and safety

- Hammering a crack closed on an ingot is unacceptable. This prevents any contained moisture from escaping during the drying process

- Standard ingot, bundles of pigs will not be accepted by railcar. (see example below)

- Ideal low profile ingot and small ingot bundles are pictured below.

- Four way RSI or Prime sows will be accepted. However, they are not preferred due to stacking instability.

Acceptable heat number marking

Acceptable heat number marking

Ideal low profile RSI

Ideal low profile RSI

Ideal small ingot/pig bundle with steel bands

Ideal small ingot/pig bundle with steel bands

Four way RSI or Prime sow - NOT preferred

Four way RSI or Prime sow - NOT preferred Small Ingot Bundles, Pigs & Slab

Specification Details

- Each bundle of ingots, pigs or slabs must be marked legibly and permanently with manufacturer's heat number.

- Any banding used to hold ingots, pigs or slabs together can be aluminum, steel, galvanized steel, or nylon.

- Banding must be intact when material arrives at Logan. Any material arriving with busted banding is subject to rejection.

- Bundles must be flat topped and designed so they can be stacked while remaining stable.

- All bundles must allow for 2-3/4 inch (70 mm) fork access for lifting.

- Mixed heats within bundles are not acceptable.

- All ingots, pigs or slabs must be skimmed.

- The maximum bundle height is 42 inches (1067mm).

- Standard ingot, bundles of pigs (See Figure 4a) will not be accepted by railcar.

- Wire rod is unaccpetable as banding. The bundles do not interlock to prevent bundle collapse and pose a safety risk.

Small ingot/pig bundle - not accepted by rail car

Small ingot/pig bundle - not accepted by rail car Small ingot/pig bundle - not accepted by rail car

Small ingot/pig bundle - not accepted by rail car Wire rod banding - not accepted at all

Wire rod banding - not accepted at all

Low Profile Sow

Specification Details

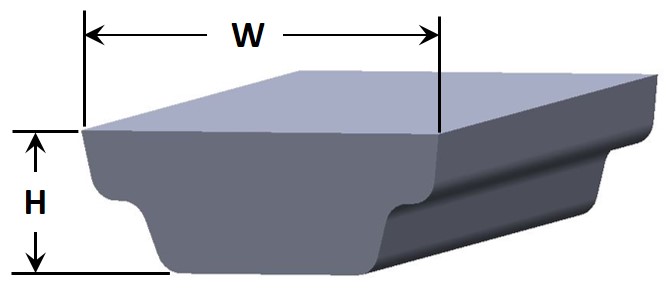

To determine if a sow is low profile, take the width (W) and divide it by the height (H). To be considered a low profile sow this value should be greater than or equal to 3. With greater than 3.5 preferred. (see illustration below)

The sow is low profile if: W / H ≥ 3

Low profile sow has been designed so that a minimum of internal shrinkage cavities form. Do not top cool sows with water which are not 100% solidified. Top cooling produces larger shrinkage cavities making it more difficult to drive out trapped moisture.

Coils

Specification Details

Coils melted at Logan include Logan scrap coils and coils returned from the customer. Logan Remelt will not melt coated coils in its round top furnaces. Environmental permits do not permit the melting of coated coils or other coated scrap. There are other recycling opportunities for coated coils. Any coils purchased outside Logan for melting at Logan must meet the SMACT definition of "clean scrap"

Clean charge means furnace charge materials, including molten aluminum; T-bar; sow; ingot; billet; pig; alloying elements; aluminum scrap known by the owner or operator to be entirely free of paints, coatings, and lubricants; uncoated/unpainted aluminum chips that have been thermally dried or treated by a centrifugal cleaner; aluminum scrap dried at 343°C (650°F) or higher; aluminum scrap delacquered/decoated at 482°C (900°F) or higher, and runaround scrap.

- No fiber cores are NOT permitted. They may contain moisture and will become a safety concern in contact with molten aluminum.

- Maximum coil weight is 58,000 lbs.

- Maximum coil width is 86 inches.

- Coils from outside Logan must have 4 digit AA alloy designation and weight legibly and permanently marked.

- Coils from inside Logan must have 6 digit alloy code and weight legibly and permanently marked.

- Coils must be banded so the tail is kept under control.

- Purchased coils must have a chemistry certification with shipping documents and must meet purchase specification

- Paper interleaved in wraps is unacceptable. See Figure 7.1 below.

- Coated coils cannot be charged in our round top furnaces. There are recycling opportunities for coated coil.

- No steel sleeves permitted.

Ingots & Ingot Butts

Specification Details

Ingots and ingot butts melted at Logan Remelt may be internal scrap or purchased scrap from outside Logan.

- Maximum ingot / ingot butt weight is 10,000 lbs. (4,536 kg) for charging directly into buckets. Scrap ingots or butts greater than 9,500 lbs. must be received and unloaded at Logan Ingot Receiving.

- Ingots greater than 10,000 (4,536 kg) must be put into melting furnace using the ingot grab. The maximum ingot grab capacity is 58,000 lbs. (28,555 kg) The Remelt grab can grip ingots up to 90 in. (223 cm) wide but not less than 50 in (127 cm). The minimum ingot length for the grab is 90 in (229 cm). The maximum ingot length is 300 in (762 cm).

- Ingots and ingot butts from outside Logan must have 4 digit AA alloy designation and weight legibly and permanently marked.

- Ingots and ingot butts from inside Logan must have 6 digit alloy code, ingot number, heat number or cast number and weight legibly and permanently marked.

- Ingots and ingot butts purchased from outside Logan must have a chemistry certification with shipping documents and must meet purchase specification.

- Rail Box Car piece/bundle limitations: Piece/Bundle must not exceed 9,500 lbs (4,536 kg), and not exceed the dimensions (length x width x height) 72 in. (183 cm) x 48 in. (122 cm) x 48 in. (122 cm).

- Rail Flat Car piece/bundle limitations: Piece/Bundle must not exceed 60,000 lbs (27,216 kg), and not exceed the dimensions (length x width x height) 300 in. (762 cm) x 72 in. (183 cm) x 30 in. (76 cm).

- Stacked material on rail cars must include spacers between the material.

- Rail Routing: Logan Aluminum, Hwy 431 North, Russellville, KY 42276. CSXT - Memphis Jct - RJCM delivery.

Tub Scrap

Specification Details

Tub scrap originates in business units downstream of Logan Remelt.

- Blue scrap tubs are for hot mill 6-inch shear scrap ONLY.

- Yellow tubs are used for all scrap other than hot mill 6-inch shear. The only time yellow tubs may be used for 6-inch shear is when no blue tubs are available.

- Maximum tub gross weight (tub and contents) is 10,000 lbs.

- Tubs must be filled with as much scrap as possible without going over the 10,000 lb limit.

- Mixed alloy scrap in tubs is NOT acceptable. Scrap must be segregated by 6 digit alloy.

- Coated scrap must not be mixed in with uncoated scrap.

- Tubs must have the proper identification ticket on both sides of the tub.

- The material in the tub must match what is on the identification ticket.

- Tubs must not be filled above the top of the tub. Filling above the top of the tub will prevent Remelt from stacking tubs and making efficient use of high bay storage areas.

- Tubs must contain only aluminum scrap. No trash permitted. (Steel, banding, cups, oily pit cleanings, etc.)

- Closed containers in scrap are not permitted.

Plate Scrap

Specification Details

Plate scrap typically originates from business units downstream of Logan Remelt but could be supplied from outside Logan. Any plate from outside Logan must meet the definition of "Clean Scrap" as defined below. The following shall apply to plate scrap.

Clean charge means furnace charge materials, including molten aluminum; T-bar; sow; ingot; billet; pig; alloying elements; aluminum scrap known by the owner or operator to be entirely free of paints, coatings, and lubricants; uncoated/unpainted aluminum chips that have been thermally dried or treated by a centrifugal cleaner; aluminum scrap dried at 343°C (650°F) or higher; aluminum scrap delacquered/decoated at 482°C (900°F) or higher, and runaround scrap.

- Mixed alloy scrap is unacceptable.

- Plates must be banded together with the total weight not exceeding 12,000 lbs.

- Length must not exceed 180 inches.

- Bundled plate must not exceed 36 inches high.

- Plate scrap from outside Logan must have 4 digit AA alloy designation legibly and permanently marked.

- Plate scrap from inside Logan must have 6 digit alloy code legibly and permanently marked.

- Must have total bundle weight marked legibly and permanently.

Coated Scrap

Coated scrap is not to be melted in Logan’s round top furnaces due to environmental, melt rate and melt loss issues. This applies to purchased material and material from other business units within Logan.

Grounds for Rejection

RSI and primary aluminum comes in many forms. Some basic rules apply to all forms supplied to Logan. Low profile sows are accepted at Logan Aluminum. Low profile sows and cut T-ingot are the preferred forms for prime aluminum. Certificates of analysis must accompany all shipments. Representative chemical samples must accompany all RSI shipments. Material outside of chemical composition as stated on the purchase order will be rejected.

Foreign Materials & Contamination

Zero Tolerance

Safety is Logan’s core value. There is zero tolerance for foreign materials and contaminants.

Foreign materials are defined as dross, pot room bath, salts, corrosion, dirt, gravel, aluminum "fines", un-melted scrap, nitrates, sulfates, oxidizers, fertilizers, unknown powders or residues, asbestos, volatile substances, non-aluminum contaminants, ammunition, closed containers, crimped tubing, PCB's, radioactive materials (2 times Background radiation), aluminum-lithium alloys, any non-aluminum materials contained inside, on the surface of or protruding from the ingot. Foreign materials are not permitted. Affected inputs may be rejected. Rejected ingots will adversely affect your performance rating.

Suppliers agree to indemnify and hold Logan Aluminum, its Associates (TAA and Novelis), and its tollers harmless from any claims, demands, cost and expenses (including reasonable attorney's fees), resulting from or arising under, in whole or in part, a breach of the foregoing warranty that their product is not contaminated with foreign materials whether caused or contributed to in whole or in part by the negligence of Logan Aluminum, its Associates (TAA and Novelis), or its tollers.

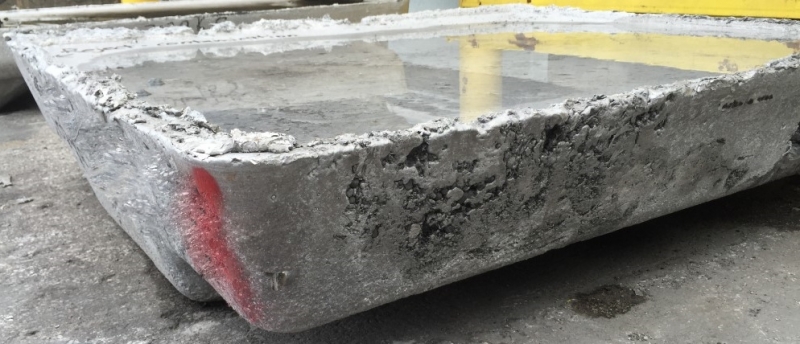

Steel lift pin left in corner of low profile RSI sow

Potroom bath imbedded in primary sow

Rotary furnace flux salt contamination

Dirt and Gravel

Severely corroded / oxidized sow

Imbedded white powder

Imbedded white powder

Various imbedded contaminants

Various imbedded contaminants

Various imbedded contaminants

Various imbedded contaminants

Various imbedded contaminants

Radioactive Contamination

Material delivered to Logan Aluminum and found to be contaminated by radiation will be handled according to Logan policy. Any material triggering a Logan radiation detector will be rejected. TAA/Logan will have the right to revoke the acceptance of the material at any time. All costs and liability associated with radioactive material will be the responsibility of the supplier. Trucks rejected for radiation are held on plant site until State Permitting is achieved. Logan's environmental team will lead the process and communication once radiation is confirmed.

Mold Release Agent

Excessive amounts unacceptable

Mold release agents are materials used to allow easy removal of ingot from casting mold.

Poor condition of casting molds often necessitates the excessive use of mold release materials. Depending on the chemistry of the mold release agent there may be serious issues at Logan.

Lime must never be used as a mold release. Lime contamination on sows is unacceptable.

Calcium bearing mold release agents may contribute to elevated calcium in the casting process. Mold release agent residues are not permitted. Affected ingots may be rejected. Possible Remedy: Casting plant to replace worn molds and/or use less mold release material. Wash mold release agent from ingots before shipment to Logan. Some RSI suppliers have had success using graphite as a mold release agent.

Worn mold and large amounts of bone ash

Bone ash contamination on RSI sows

Rough Edges

Rough edges or flashing

Rough sharp edges protruding 1" or greater from the ingot edge. This type of defect is not acceptable and poses a safety hazard for anyone walking close to this material. There is zero tolerance and the metal will be rejected. The appropriate Associate will be informed and the issue documented.

Dross & Skimming

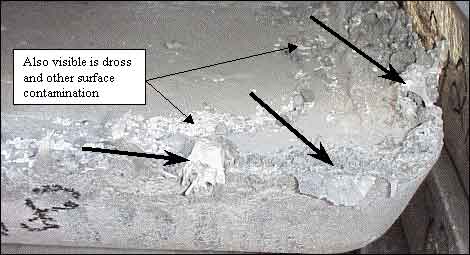

Dross Contamination, Inclusions

All ingots must be skimmed. Un-skimmed or poorly skimmed ingots are unacceptable. (see examples below) Placing dross and skimmings in the bottom of a mold to be filled is also not acceptable. Packing dross against the mold wall of solidifying ingots is unacceptable. Pouring molten aluminum onto dross or skimmings is a potential safety issue for the sow casting plant as well as for Logan. The owners of Logan Aluminum purchase aluminum and aluminum alloys and not aluminum oxide. Un-skimmed ingots will be rejected. Poorly skimmed ingots and ingots with imbedded skimmings may be rejected.

Ideally skimmed ingot

Ingot showing dross not skimmed off

Dross / Skimmings cast into ingot

Shrinkage Cavities & Voids

Correct Cooling Procedure

Do not top cool sows with water which are not 100% solidified. Top cooling produces larger shrinkage cavities making it more difficult to drive off trapped moisture. Cooling from the bottom and sides of an ingot helps reduce the size of shrinkage cavities. See the Aluminum Association Guidelines for Aluminum Sow Casting and Charging. The Aluminum Association website is www.aluminum.org

Additionally, sows with voids/large thick skinned bubbles will not be accepted. A sow with the same features shown below was implicated in a recent molten metal explosion. The photo on the right shows a large bump that was broken open to show that there is a void.

Double, Multiple or Non-Continuous Pouring

Zero Tolerance

Double poured, non-continuously poured sows must never be shipped to Logan - they will be rejected.

Meltable Qualification Process

Evaluation

Procurement Inspection

Logan evaluates Meltables before they are approved for use. Quality planning for new meltables includes some of the following aspects:

- Consider blending/alloying issues.

- Consider metal cleanliness and recovery issues.

- Review manufacturing technique.

- Review geometry relative to preheating requirements.

- Review Preheat requirements if applicable.

- Perform chemistry crosscheck evaluation as needed.

- Consider the Logan or Vendor chemical analysis system capability for the chemistry in question.

- Review packaging, handling and storage logistics.

- Evaluate compatibility with current process and/or machine capability (ingot size, shape, bundle weights, etc.).

- Assess environmental, safety and health risks with consultation of Environmental as needed.

- Perform trials as needed and document using the Process Practice Change System.

- No Residual lubricant may be present on scrap, unless otherwise agreed upon. Scrap must be free and clean of oil or lube. Based on Logan's compliance to SMACT standards certain furnaces are regulated as "Clean Charge" furnaces only. "Clean Charge" is defined in SMACT regulations (40 CFR 1503).

Clean charge means furnace charge materials, including molten aluminum; T-bar; sow; ingot; billet; pig; alloying elements; aluminum scrap known by the owner or operator to be entirely free of paints, coatings, and lubricants; uncoated/unpainted aluminum chips that have been thermally dried or treated by a centrifugal cleaner; aluminum scrap dried at 343°C (650°F) or higher; aluminum scrap delacquered/decoated at 482°C (900°F) or higher, and runaround scrap.