Last updated on October 20th, 2023 at 02:38 pm

TAA Metal Specification

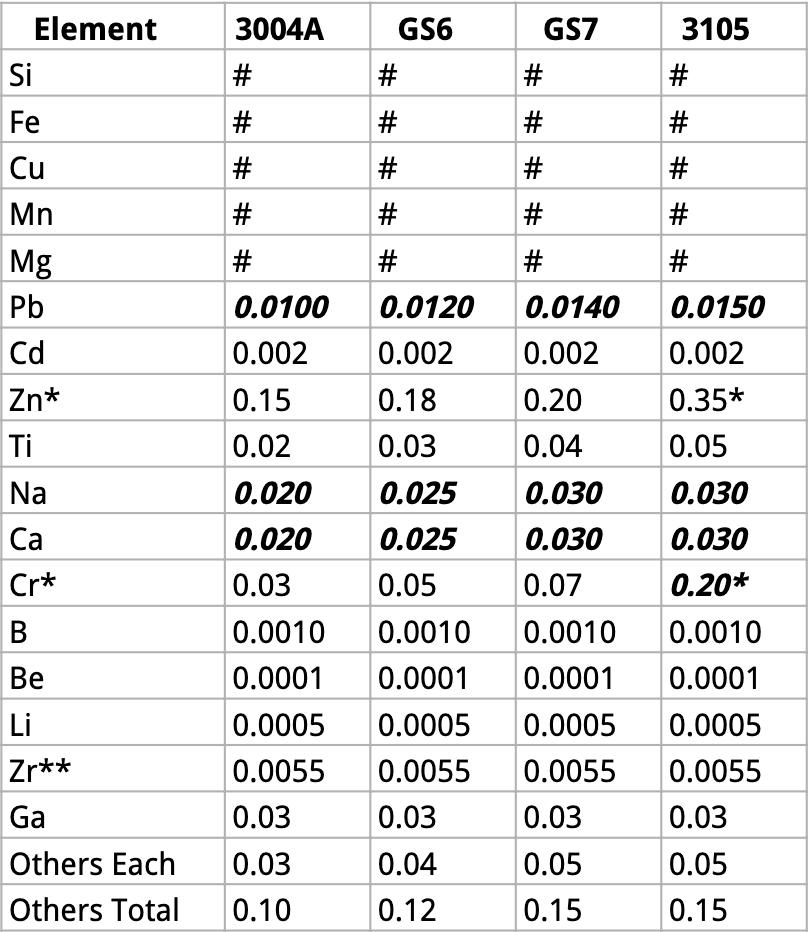

Chemical Limits

The chemical limits below do not apply to metal recovered from Logan dross. Element reporting at the bottom of this page does apply to metal recovered from Logan dross.

# Refer to your supply contract for these limits. You may also contact Tri-Arrows Aluminum Inc. for more details.

*Preferred Cr <0.15 an Zn <0.30

| Element | 5182A | 5182B | 5182C |

|---|---|---|---|

| Si | 0.12 | 0.14 | 0.17 |

| Fe | 0.28 | 0.30 | 0.33 |

| Cu | 0.05 | 0.07 | 0.10 |

| Mn | 0.43 | 0.45 | 0.47 |

| Mg | 5.0-6.0 | 4.5-6.0 | 3.0-6.0 |

| Pb | 0.0100 | 0.0110 | 0.0120 |

| Cd | 0.002 | 0.003 | 0.005 |

| Zn | 0.05 | 0.07 | 0.10 |

| Ti | 0.05 | 0.06 | 0.07 |

| Na | 0.003 | 0.003 | 0.003 |

| Ca | 0.030 | 0.030 | 0.035 |

| Cr | 0.04 | 0.05 | 0.06 |

| B | 0.0010 | 0.0010 | 0.0010 |

| Be | 0.0001 | 0.0001 | 0.0001 |

| Li | 0.0005 | 0.0005 | 0.0005 |

| Zr** | 0.0055 | 0.0055 | 0.0055 |

| Ga | 0.03 | 0.03 | 0.03 |

| Others Each | 0.03 | 0.04 | 0.05 |

| Others Total | 0.10 | 0.12 | 0.15 |

# Refer to your supply contract for these limits. You may also contact Tri-Arrows Aluminum Inc. for more details.

The above are maximums expressed in percent of total

Others each includes: Bi, Ni, Sn, V

Others total includes: Ti, Na, Ca, Cd, Pb, Be, Ni, Cr, Sn, V, B.

The maximum Zr level per heat in a shipment is 0.0055%. Zr contamination typically comes from some Mg alloys or some 7000 series scrap. Zr analysis from the supplier is required as indicated by the Element Reporting Requirements table below.

Must be low profile sow or standard T-Bar. All pieces must be marked with heat number

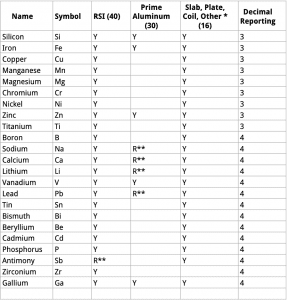

Element Reporting Requirements

Element Reporting Requirements for RSI and primary aluminum are shown below.

* Aluminum alloys, excludes prime aluminum and RSI

** R=Recommended

Lithium

Primary aluminum from reduction plants using Lithium in their process is not acceptable. The maximum allowed Li is 0.0005% (5 ppm) for all grades of primary aluminum unless otherwise agreed upon.

RSI Sow Heat Variation

Maximum heat variation for all TAA Specs must be no greater than 150% of the average per element. Heat variation greater than 150% of the average per element will not be accepted without prior approval from TAA.

Italicized or bolded elements in the specification tables above are absolute maximums by heat, unless otherwise approved in advance of shipment.

Loading of RSI Sow

Please load heats on truck/railcar in the same order as listed on the COA sheet. This does not apply to prime aluminum.

For additional shipping requirements, please visit our RSI/Prime/Meltable Shipping & Receiving page.

Prime Standards

Aluminum Association Gold Sheets - International Designations and Chemical Composition Limits for Unalloyed Aluminum - North American and International Registration Record, March, 2007 can be obtained from: http://www.aluminum.org